BLOG

Understanding 1/2 to 1/4 Nipple ID: A Comprehensive Guide

Introduction

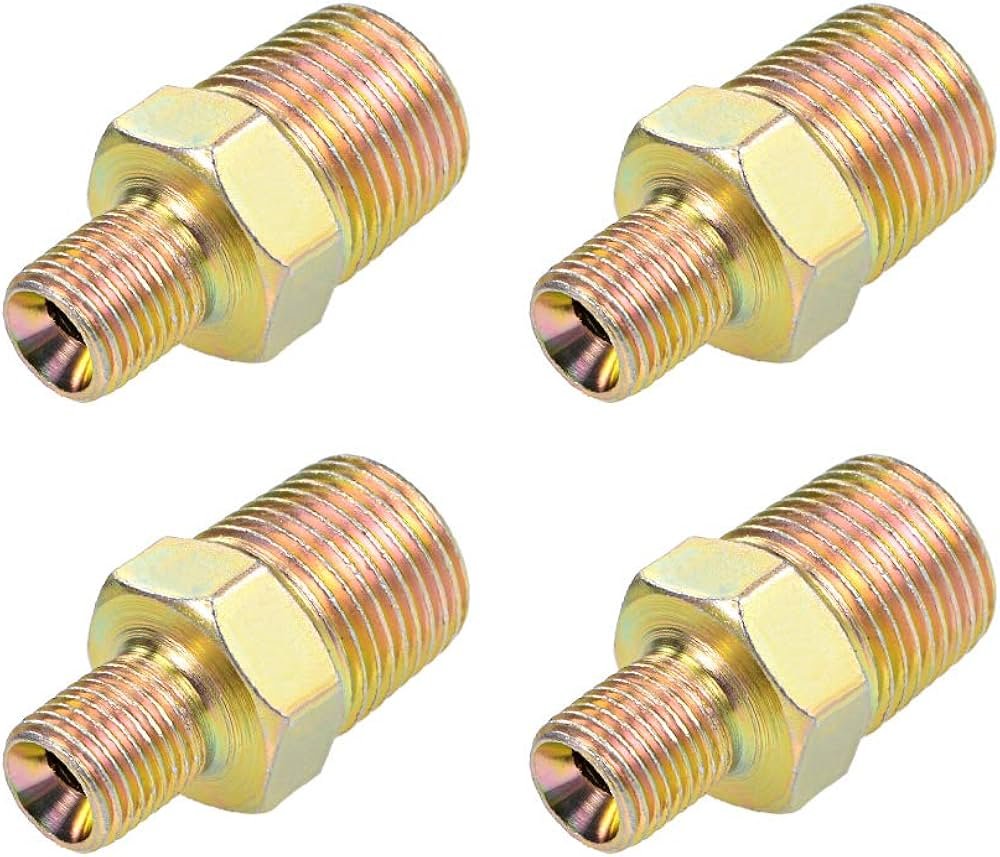

When it comes to plumbing, heating, or industrial applications, understanding pipe fittings is crucial. Among these fittings, nipple fittings are essential components that play a vital role in connecting two other fittings or pipes. In this blog, we’ll explore the significance of nipple fittings, particularly focusing on 1/2 to 1/4 nipple ID (inside diameter). We’ll delve into their uses, materials, installation techniques, and much more, ensuring you have a thorough understanding of these critical components.

What is a Nipple Fitting?

A nipple fitting is a short length of pipe that has threads on both ends. They are used to connect two other fittings or pipes in various plumbing and heating systems. Nipples come in various sizes and types, with the most common being standard threaded nipples, which can be made from various materials such as brass, stainless steel, or PVC.

Types of Nipple Fittings

1. Straight Nipples: These have the same diameter at both ends and are used to connect two fittings in a straight line.

2. Reducing Nipples: These feature different diameters on each end, allowing you to connect a larger pipe to a smaller one. For example, a 1/2 to 1/4 nipple fitting is a reducing nipple.

3. Close Nipples: These are short lengths of pipe that are typically used in tight spaces. They are designed to have minimal length while maintaining functionality.

Why Are Nipple Fittings Important?

Nipple fittings are essential in plumbing and heating systems because they provide a secure connection between different components. Their role is critical in ensuring the efficient flow of liquids or gases through a system. Properly installed nipple fittings can help prevent leaks, ensure system integrity, and maintain overall functionality.

Understanding 1/2 to 1/4 Nipple ID

Definition of Nipple ID

Nipple ID refers to the inside diameter of a nipple fitting. In our case, a 1/2 to 1/4 nipple ID means that one end of the nipple has an inside diameter of 1/2 inch, while the other end has an inside diameter of 1/4 inch. This type of nipple fitting allows for a reduction in pipe size, making it suitable for various applications, including water supply lines, heating systems, and gas lines.

Applications of 1/2 to 1/4 Nipple ID

1. Plumbing Systems: In plumbing, 1/2 to 1/4 nipple fittings are often used to connect pipes of different sizes, enabling efficient water flow throughout a system.

2. Heating Systems: These nipples can connect different components of heating systems, such as radiators and boilers, facilitating the transfer of hot water or steam.

3. Gas Lines: In gas applications, nipple fittings help connect gas pipes, ensuring the safe delivery of gas to appliances.

Advantages of Using 1/2 to 1/4 Nipple ID

Versatility: These nipple fittings can be used in various applications, making them a versatile choice for both residential and commercial projects.

Ease of Installation: They can be easily installed in tight spaces where other fittings may not fit, saving time and effort during installation.

Cost-Effectiveness: Nipple fittings are generally more affordable compared to other fitting types, making them an economical choice for pipe connections.

Materials Used in Nipple Fittings

The material of a nipple fitting is crucial for determining its performance, durability, and application suitability. Here are some common materials used for 1/2 to 1/4 nipple fittings:

1. Brass

Properties: Brass is an alloy of copper and zinc, known for its strength and corrosion resistance.

Applications: It is commonly used in plumbing applications where water flow is involved, due to its ability to resist rust and corrosion.

2. Stainless Steel

Properties: Stainless steel is known for its durability, resistance to high temperatures, and corrosion resistance.

Applications: Ideal for gas lines, heating systems, and applications where hygiene is crucial, such as food processing.

3. PVC

Properties: PVC (polyvinyl chloride) is a lightweight plastic that is resistant to corrosion and chemical damage.

Applications: Used in plumbing applications where flexibility and resistance to harsh chemicals are required, such as irrigation systems.

Choosing the Right Nipple Fitting

When selecting a nipple fitting for your project, consider the following factors:

1. Size

Choose the correct size based on the pipe dimensions. In this case, a 1/2 to 1/4 nipple fitting is appropriate for connecting a 1/2-inch pipe to a 1/4-inch pipe.

2. Material

Select the right material based on the application. Consider factors like temperature, pressure, and the type of fluid (water, gas, chemicals) that will flow through the system.

3. Thread Type

Nipple fittings come with different thread types, such as NPT (National Pipe Thread) or BSP (British Standard Pipe). Ensure that the thread type matches the fittings you are connecting to avoid leaks or compatibility issues.

Installation of 1/2 to 1/4 Nipple ID

Installing a nipple fitting is a straightforward process, but it’s essential to follow proper procedures to ensure a secure connection. Here’s a step-by-step guide:

Tools Required

Pipe wrenches or adjustable wrenches

Teflon tape (for threaded connections)

Pipe cleaner or brush (for cleaning threads)

Step-by-Step Installation Process

1. Preparation:

Gather all necessary tools and materials.

Ensure that the pipes you will be connecting are clean and free of debris.

2. Apply Teflon Tape:

Wrap Teflon tape around the threaded ends of the nipple fitting. This helps create a watertight seal and prevents leaks.

3. Connect the Nipple:

Insert one end of the nipple fitting into the corresponding pipe fitting. Hand-tighten it first to ensure proper alignment.

Use a wrench to tighten the fitting further, ensuring a secure connection without over-tightening, which can damage the threads.

4. Repeat for the Other End:

Connect the other end of the nipple fitting to the second pipe fitting, repeating the same steps.

5. Check for Leaks:

Once both ends are connected, turn on the water or gas supply slowly.

Inspect the connections for leaks. If you notice any, tighten the fittings as necessary.

Safety Precautions

Always wear appropriate safety gear when working with plumbing or gas systems.

Ensure the system is depressurized and drained before installation to prevent spills or accidents.

If working with gas lines, consult a professional if you are unsure about the installation process.

Maintenance of Nipple Fittings

Maintaining your nipple fittings is essential for ensuring their longevity and functionality. Here are some tips for proper maintenance:

1. Regular Inspections

Periodically check for leaks or signs of corrosion. Address any issues immediately to prevent further damage.

2. Clean the Area

Keep the area around the fittings clean and free of debris. This helps prevent corrosion and allows for easier inspections.

3. Replace Damaged Fittings

If you notice any cracks, rust, or damage to your nipple fittings, replace them immediately to ensure the integrity of the system.

4. Professional Servicing

For complex systems or gas lines, consider scheduling regular professional maintenance checks to ensure everything is functioning correctly.

Common Issues with Nipple Fittings

While nipple fittings are generally reliable, certain issues can arise. Here are some common problems and solutions:

1. Leaking Connections

Causes: Leaks often occur due to improper installation, damaged threads, or worn-out seals.

Solutions:

Tighten the fittings carefully, ensuring not to overtighten.

If leaks persist, disassemble the fitting and inspect for damaged threads or seals, replacing them as needed.

2. Corrosion

Causes: Corrosion can happen due to moisture exposure, especially in metal fittings.

Solutions:

Regularly inspect and clean fittings to remove any corrosion.

Consider using corrosion-resistant materials like stainless steel for long-term applications.

3. Cracking or Breaking

Causes: Over-tightening, extreme temperatures, or age can lead to cracking.

Solutions:

Ensure proper installation techniques are followed.

Replace damaged fittings immediately to avoid system failure.

Conclusion

Understanding 1/2 to 1/4 nipple ID fittings is essential for anyone involved in plumbing, heating, or industrial applications. These fittings are versatile, cost-effective, and play a crucial role in connecting pipes and ensuring efficient fluid flow. By choosing the right material, following proper installation techniques, and maintaining your fittings, you can ensure a reliable and long-lasting plumbing system.

As you explore the world of nipple fittings, remember that attention to detail and adherence to best practices will contribute to the overall success of your projects. Whether you’re a DIY enthusiast or a professional plumber, having a solid understanding of nipple fittings will help you achieve the best results in your work.

Share this content:

BLOG

Your Topics | Multiple Stories to Educate and Inspire

In today’s fast-paced world, stories are a powerful medium to entertain, educate, and inspire. Whether you’re looking for motivational tales, fictional escapes, or informative narratives, exploring your topics | multiple stories can open up a world of knowledge and creativity. This blog will dive into various types of stories that captivate readers and leave lasting impressions.

Why Stories Are Important

Stories have always been a fundamental way of sharing experiences, knowledge, and culture. They allow us to connect with others, understand different perspectives, and explore emotions. With your topics | multiple stories, you can find narratives that resonate with your interests, making every read both enjoyable and meaningful.

Inspiring Real-Life Stories

1. Overcoming Adversity

One of the most compelling categories within your topics | multiple stories is about individuals overcoming challenges. From people battling life-threatening illnesses to entrepreneurs building businesses from scratch, these stories remind us of the power of resilience and determination.

Take, for example, a tale of a small-town athlete who faced financial struggles but went on to win international medals. Such stories inspire and motivate others to chase their dreams, no matter the obstacles.

2. Acts of Kindness

Stories of kindness and generosity can warm your heart and restore your faith in humanity. Whether it’s about strangers helping each other in emergencies or communities coming together to aid those in need, these stories are a valuable part of your topics | multiple stories.

Fictional Tales That Spark Creativity

If you’re someone who loves to escape reality for a while, fictional stories are your gateway to a world of imagination.

1. Adventures in Fantasy Worlds

Fantasy stories transport readers to magical lands filled with heroes, villains, and mythical creatures. They provide an escape from the mundane and encourage us to dream big. In your topics | multiple stories, fantasy adventures often feature narratives of bravery, friendship, and hope that resonate with readers.

2. Gripping Mysteries

Mystery stories keep readers on the edge of their seats. A well-crafted mystery engages the mind, prompting readers to solve puzzles and uncover secrets. These stories are an exciting addition to any collection of your topics | multiple stories, appealing to both casual and avid readers.

Educational Narratives for Growth

Not all stories are meant for entertainment—many are designed to educate and inform.

1. Historical Accounts

History comes alive through stories. By exploring the lives of historical figures or pivotal events, readers can better understand the world and its complexities. Historical narratives are a significant part of your topics | multiple stories, helping us learn from the past.

2. Science and Innovation

Stories about groundbreaking scientific discoveries or technological advancements are fascinating and inspiring. They showcase human ingenuity and highlight the importance of curiosity and perseverance.

The Impact of Sharing Your Own Stories

Have you ever thought about sharing your story? Every individual has a unique journey worth telling. Contributing to your topics | multiple stories allows you to connect with others who may relate to your experiences.

For instance:

- Did you overcome a personal challenge?

- Have you embarked on a life-changing adventure?

- Do you have a lesson that could benefit others?

Your story might inspire someone to take the first step toward their own dreams.

How to Find and Share Stories

The internet offers a wealth of platforms to discover and share stories. From personal blogs to social media and online forums, the opportunities are endless. If you’re looking for high-quality narratives, explore curated collections or websites dedicated to your topics | multiple stories.

When sharing your story, consider these tips:

- Keep it Authentic: Share your genuine experiences and emotions.

- Engage Your Audience: Use a relatable tone and clear language.

- Optimize for SEO: If you’re publishing online, ensure your content is optimized to reach a broader audience.

Conclusion

Stories are a universal language that inform, entertain, and inspire. By diving into your topics | multiple stories, you can discover a wide range of narratives that align with your interests and goals. Whether it’s a tale of personal triumph, a fictional adventure, or an educational insight, stories enrich our lives in countless ways.

Take a moment today to explore new stories or share your own. You never know how a single narrative could impact someone’s life or provide them with the inspiration they need.

Share this content:

BLOG

The Ultimate Guide to Torrent Sites in 2024: Everything

Torrent sites are a popular way for millions of people worldwide to share and download files. From movies and TV shows to software, music, and eBooks, torrents have revolutionized how digital content is distributed. But not all torrent sites are created equal, and using them responsibly requires understanding the risks and benefits. In this blog, we’ll dive into everything you need to know about torrent sites in 2024.

What Are Torrent Sites?

Torrent sites are online platforms that host torrent files and magnet links, allowing users to download and share content using peer-to-peer (P2P) file-sharing technology. Instead of downloading files from a single server, torrents divide the content into smaller parts shared among multiple users (peers). This decentralized approach increases download speeds and reduces server costs.

Popular torrent clients like uTorrent, BitTorrent, and qBittorrent enable users to access and manage torrent files easily.

Top Torrent Sites in 2024

1. The Pirate Bay

Overview: Often called the “king of torrents,” The Pirate Bay has been a favorite for years. It hosts a vast library of torrents, including movies, games, music, and software.

Pros: High availability, user-friendly interface, and a strong community for verifying files.

Cons: Frequent domain changes and legal scrutiny in several countries.

2. RARBG

Overview: Known for its high-quality content, especially in movies and TV shows, RARBG stands out for providing detailed descriptions and screenshots.

Pros: Quality assurance and excellent seeder-to-leecher ratios.

Cons: Restricted access in several countries.

3. 1337x

Overview: This user-friendly site is perfect for beginners. It offers a broad range of content, including trending TV shows, games, and software.

Pros: Modern design and active user reviews for safe downloads.

Cons: Some torrents may have fewer seeders.

4. YTS

Overview: Focused on high-quality movie torrents, YTS is ideal for those who want smaller file sizes without compromising quality.

Pros: Compact file sizes and excellent video quality.

Cons: Limited to movies; no software or games.

5. EZTV

Overview: A go-to torrent site for TV show enthusiasts. It offers a wide selection of episodes from classic and current series.

Pros: Consistent updates and easy navigation.

Cons: Ads can be intrusive.

Is Downloading from Torrent Sites Legal?

This question doesn’t have a one-size-fits-all answer. Torrenting itself is not illegal—it’s a technology. However, the legality of downloading or sharing files depends on the content. For example:

Legal Torrents: Open-source software, public domain content, and files with explicit permission for sharing.

Illegal Torrents: Copyrighted movies, music, or software shared without authorization.

Downloading illegal content can result in fines, lawsuits, or even jail time, depending on local laws. Always verify the legality of the files before downloading.

Risks of Using Torrent Sites

While torrenting offers convenience, it comes with several risks:

1. Malware and Viruses

Torrent files can sometimes include malicious software. Downloading from unverified sources may infect your device with malware or ransomware.

2. Privacy Concerns

Since torrenting relies on P2P sharing, your IP address is visible to other users in the network. Hackers or even government agencies can track your activity.

3. Legal Issues

Using torrent sites to download copyrighted content may lead to penalties or legal action.

4. Fake Torrents

Some torrents are misleading and may contain harmful or irrelevant content.

How to Torrent Safely

To reduce risks while using torrent sites, follow these best practices:

1. Use a VPN

A Virtual Private Network (VPN) hides your IP address, encrypts your connection, and ensures privacy while torrenting. Top VPNs for torrenting include NordVPN, ExpressVPN, and CyberGhost.

2. Choose Trusted Sites

Stick to reputable torrent sites like The Pirate Bay, 1337x, or RARBG. Avoid unknown platforms with limited user reviews.

3. Check Seeder-to-Leecher Ratio

Files with a high number of seeders download faster and are usually more reliable.

4. Install Antivirus Software

A robust antivirus program protects your device from malware embedded in torrent files.

5. Read Reviews

Check user comments and ratings on torrent files before downloading. Verified torrents are less likely to have harmful content.

Legal Alternatives to Torrenting

For those seeking a safer and legal way to access content, consider the following alternatives:

1. Streaming Services: Platforms like Netflix, Amazon Prime, Hulu, and Disney+ offer extensive libraries of movies and shows.

2. Free Content Platforms: Websites like YouTube and Vimeo provide legal access to free videos and music.

3. Open-Source Resources: Websites like Project Gutenberg and Free Music Archive offer public domain books and music.

The Future of Torrent Sites

As governments worldwide crack down on illegal torrenting, the landscape of torrent sites continues to evolve. New sites emerge, while established ones adapt to avoid legal consequences. In 2024, using torrent sites responsibly and securely is more important than ever.

Conclusion

Torrent sites remain a valuable resource for sharing and downloading files, but they come with responsibilities and risks. Always prioritize safety by using trusted sites, enabling VPNs, and avoiding illegal content. By doing so, you can enjoy the benefits of torrenting without compromising your security or facing legal troubles.

FAQs

1. Are torrent sites free to use?

Yes, most torrent sites are free, but some may include premium options or donations.

2. Can torrenting harm my computer?

Downloading files from untrusted sources can expose your device to malware or viruses. Use antivirus software to stay protected.

3. Is a VPN necessary for torrenting?

Yes, a VPN ensures privacy and security by hiding your IP address and encrypting your connection.

4. What are the best alternatives to torrenting?

Streaming services like Netflix or legal open-source platforms like Project Gutenberg offer safe alternatives.

By staying informed and cautious, you can navigate the torrenting world effectively in 2024.

Share this content:

BLOG

Kennedy Funding Lawsuit: An Overview

Kennedy Funding Lawsuit: An Overview

Kennedy Funding, a well-known name in the commercial real estate financing sector, has faced its share of challenges over the years. Among these are legal battles that have garnered attention, particularly lawsuits involving allegations of misconduct, disputes over funding agreements, or other issues. This blog provides an in-depth look at the Kennedy Funding lawsuit, exploring its background, potential implications, and what it signifies for borrowers, lenders, and the real estate financing industry.

What is Kennedy Funding?

Kennedy Funding is a global direct private lender specializing in bridge loans for real estate transactions. The firm is renowned for its ability to provide funding quickly, often for high-risk or unconventional projects that traditional banks might avoid. These include:

Commercial real estate loans

Land acquisition financing

Construction loans

Restructuring debt

While Kennedy Funding has helped many clients secure financing for critical projects, its unconventional lending approach has occasionally led to legal disputes.

Background of the Kennedy Funding Lawsuit

The lawsuits involving Kennedy Funding typically stem from disagreements over loan terms, allegations of breach of contract, or accusations of misleading practices. Borrowers or business partners may file claims if they feel misrepresented or believe the lender has failed to honor its commitments.

Some common issues that have been highlighted in lawsuits include:

1. Loan Disputes

Borrowers may claim that loan terms were not adequately disclosed or that Kennedy Funding failed to deliver promised financing within agreed timelines. These disputes often arise in high-stakes real estate projects where delays can have significant financial repercussions.

2. Breach of Contract

Accusations of breaching loan agreements are another common theme in lawsuits. Borrowers or partners may allege that Kennedy Funding failed to adhere to agreed-upon terms, leading to project delays or financial losses.

3. Predatory Lending Accusation

Some lawsuits have accused Kennedy Funding of engaging in predatory lending practices, such as imposing high-interest rates or hidden fees that borrowers claim were not transparent at the outset.

4. Misrepresentation

Borrowers might argue that they were misled about the nature or terms of their loans, leading to financial strain or an inability to complete projects as planned.

Key Takeaways from Kennedy Funding Lawsuits

The lawsuits surrounding Kennedy Funding highlight critical lessons for borrowers and lenders alike. Here are some key takeaways:

1. Transparency is Crucial

Both borrowers and lenders must prioritize transparency in all financial dealings. Clear communication about loan terms, interest rates, fees, and timelines can prevent misunderstandings and disputes.

2. Thorough Documentation

Legal disputes often hinge on documentation. Borrowers should ensure that all agreements are in writing and reviewed by legal counsel before signing. Similarly, lenders like Kennedy Funding must maintain detailed records of all transactions and agreements.

3. Due Diligence is Key

Borrowers must conduct due diligence on lenders, especially when working with non-traditional financing sources. Understanding a lender’s reputation, past lawsuits, and track record can help avoid potential pitfalls.

4. Legal Recourse is an Option

In cases where disputes cannot be resolved amicably, legal recourse may be necessary. Borrowers and lenders alike should be prepared for the financial and reputational costs of lawsuits.

Implications for Borrowers

Borrowers considering working with Kennedy Funding or similar private lenders should take note of the potential risks highlighted by these lawsuits. Here are some steps to mitigate risks:

Understand the Terms: Ensure you fully understand loan terms, including interest rates, repayment schedules, and any penalties for non-compliance.

Seek Legal Advice: Before signing any agreements, consult with legal and financial advisors to ensure the terms are fair and enforceable.

Plan for Contingencies: High-risk projects often face unforeseen challenges. Borrowers should have contingency plans in place to address delays or funding issues.

Implications for Kennedy Funding

For Kennedy Funding, lawsuits can impact its reputation and client trust. To maintain credibility and continue operating successfully, the company should:

Enhance Transparency: Providing clear, comprehensive documentation and addressing borrower concerns proactively can help rebuild trust.

Strengthen Compliance: Ensuring compliance with all regulatory requirements and industry best practices is essential for avoiding future disputes.

Focus on Customer Relations: Building strong relationships with clients and addressing complaints swiftly can mitigate the risk of lawsuits.

Broader Impact on the Real Estate Financing Industry

The Kennedy Funding lawsuit is not an isolated event; it reflects broader challenges in the real estate financing sector, particularly in the realm of private lending. Key takeaways for the industry include:

Regulatory Oversight: Increased scrutiny from regulators could help ensure fair lending practices and protect borrowers from potential misconduct.

Evolving Business Models: Lenders may need to adapt their business models to align with borrower expectations and legal standards.

Education for Borrowers: Borrowers must be educated about their rights and responsibilities when securing financing, particularly from non-traditional lenders.

Conclusion

The Kennedy Funding lawsuit serves as a cautionary tale for both borrowers and lenders in the real estate financing space. While Kennedy Funding has built a reputation as a fast and flexible lender, legal disputes underscore the importance of transparency, thorough documentation, and due diligence.

For borrowers, understanding the terms of any loan agreement and seeking professional advice can prevent costly mistakes. For lenders, maintaining ethical practices and addressing client concerns proactively is critical for long-term success.

As the real estate financing industry evolves, cases like the Kennedy Funding lawsuit remind us that trust, transparency, and accountability are essential for navigating high-stakes transactions. Whether you’re a borrower or lender, these lessons are invaluable for achieving success while minimizing risks.

Share this content:

-

Health6 months ago

Health6 months agoВетеринарная клиника VetCityPets: Забота о вашем питомце на высшем уровне

-

App6 months ago

App6 months agoExperience Unlimited Entertainment with Castle APK for Android

-

Business8 months ago

Business8 months agoSnow Day Calculator: How to Predict School Closures

-

AI8 months ago

AI8 months agoUnderstanding 라마 3.1: Features, Benefits, and Applications

-

Business7 months ago

Business7 months agoLand Rover Defender vs. Toyota Land Cruiser: Battle of the Luxury Off-Roaders

-

Ronaldo8 months ago

Ronaldo8 months agoRonald Acuña Jr.: The Rise of a Baseball Superstar

-

Travel6 months ago

Travel6 months agoExplore Mega-Personal.net Travel Archives: Your Gateway

-

BLOG8 months ago

BLOG8 months agoThe Ultimate Guide to Becoming a Car Guru: Tips for Car Enthusiasts and Buyers